Warehouses present unique challenges in structural engineering. Foundations must support heavy loads from stored goods and equipment while maintaining flexibility for future modifications. Ensuring structural integrity and minimizing risks like cracking or punching shear failures is critical. Additionally, coordinating complex reinforcement plans often leads to errors and delays, affecting overall project timelines and costs.

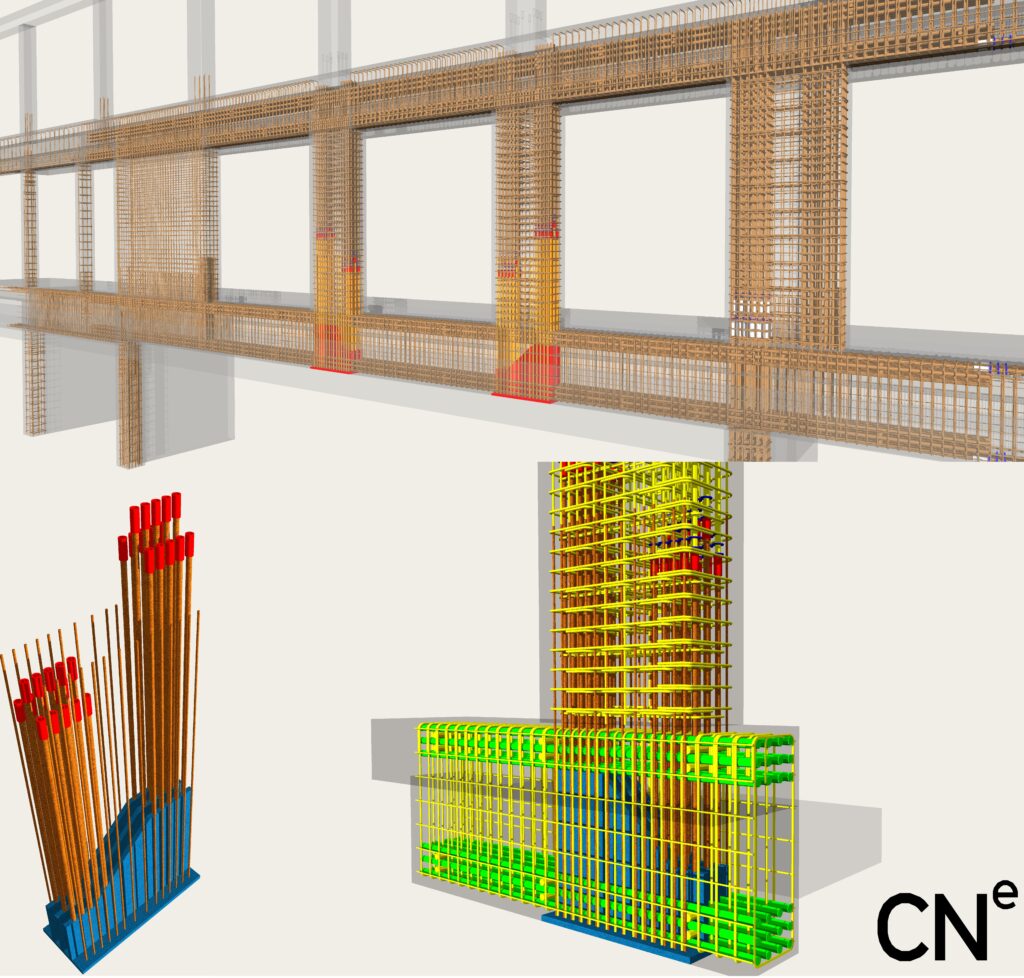

Building Information Modeling (BIM) helps address these challenges by providing a clear, comprehensive view of all structural elements and facilitating better collaboration among stakeholders. In our recent project for a warehouse in Freilassing, Germany, CN Europlan utilized BIM alongside ALLPLAN software to streamline the design and implementation of an effective reinforcement strategy.

Project Overview: Freilassing Warehouse

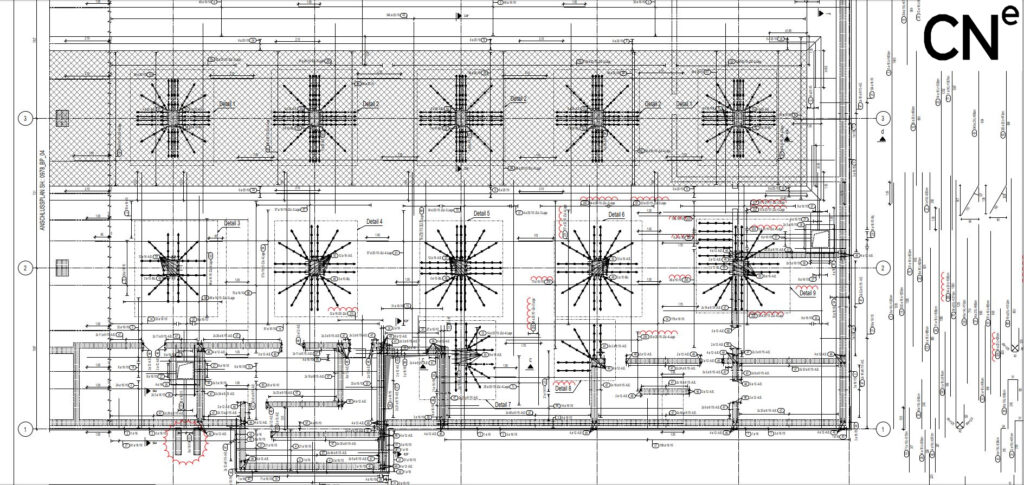

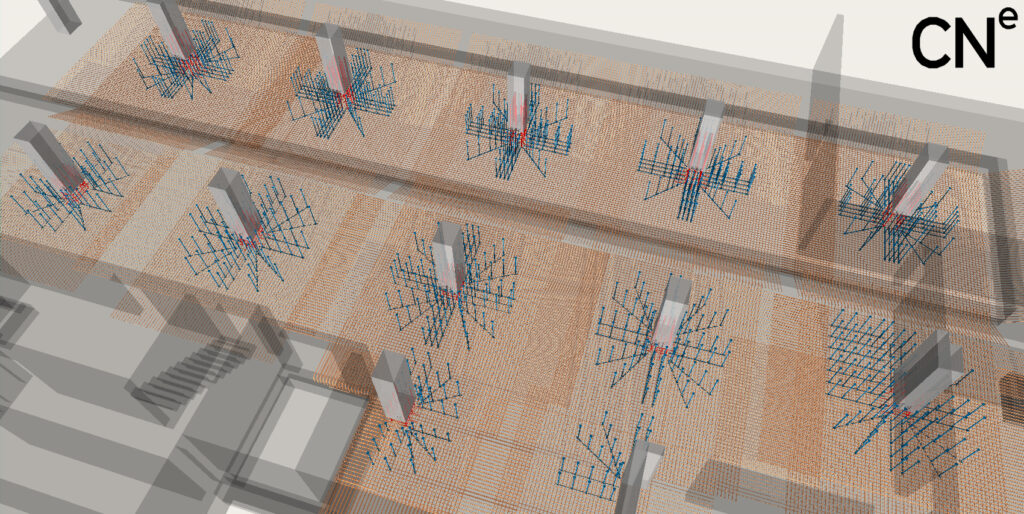

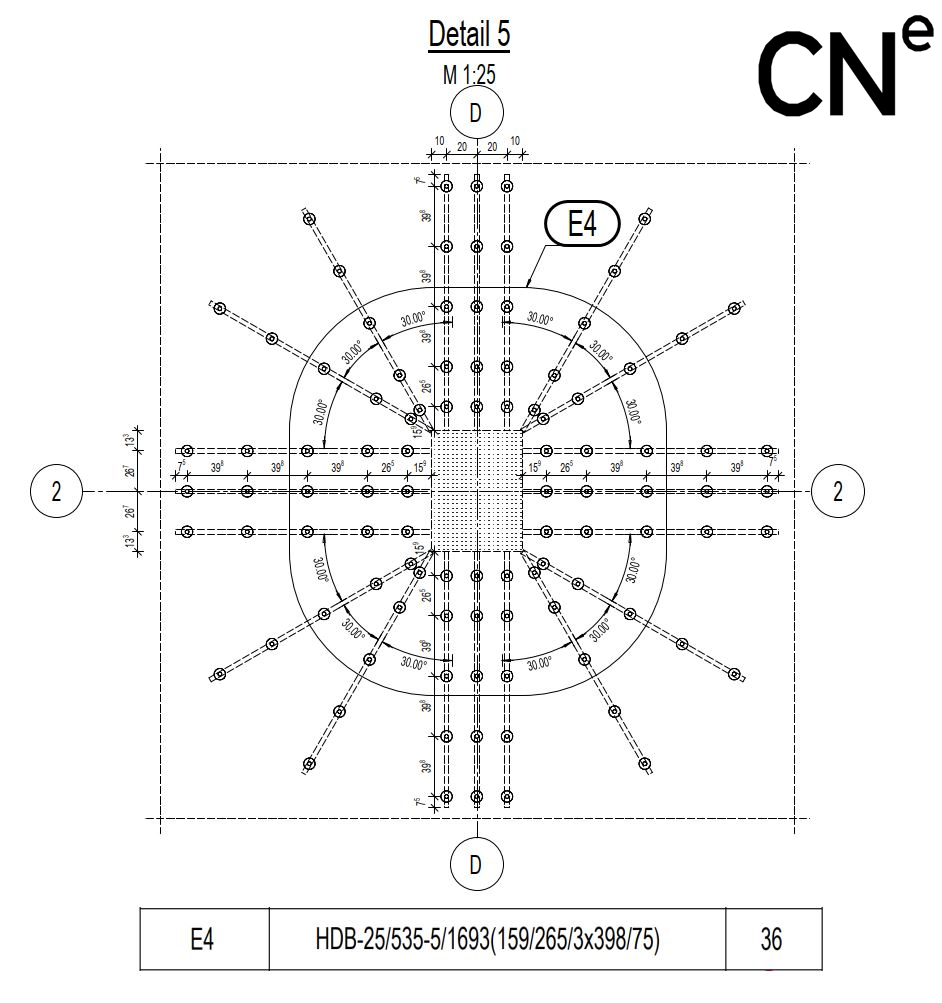

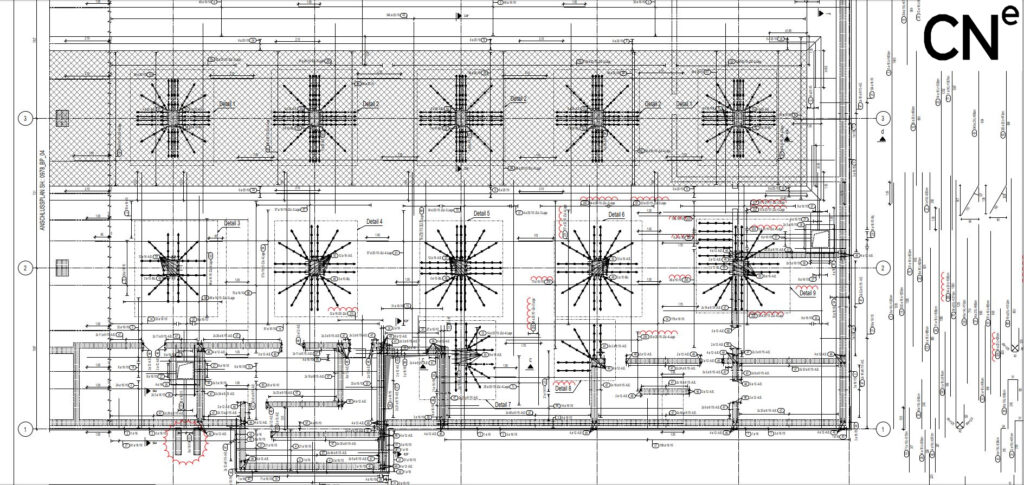

For the Freilassing warehouse, the bottom plate required significant reinforcement to handle heavy loads and prevent structural issues over time. Our solution involved the use of additional rebars and Halfen Punching Rails specifically for the bottom plate. These elements were designed to enhance the foundation’s strength and durability, minimizing the risk of cracking and punching shear failures.

Reinforcement Strategy: Rebars and Punching Rails by Halfen

To ensure a robust foundation, we combined additional rebars with Halfen Punching Rails:

- Rebars were strategically placed to improve the tensile strength of the concrete. By reinforcing the concrete slab, the rebars help distribute loads evenly, reducing the risk of structural damage under heavy load conditions.

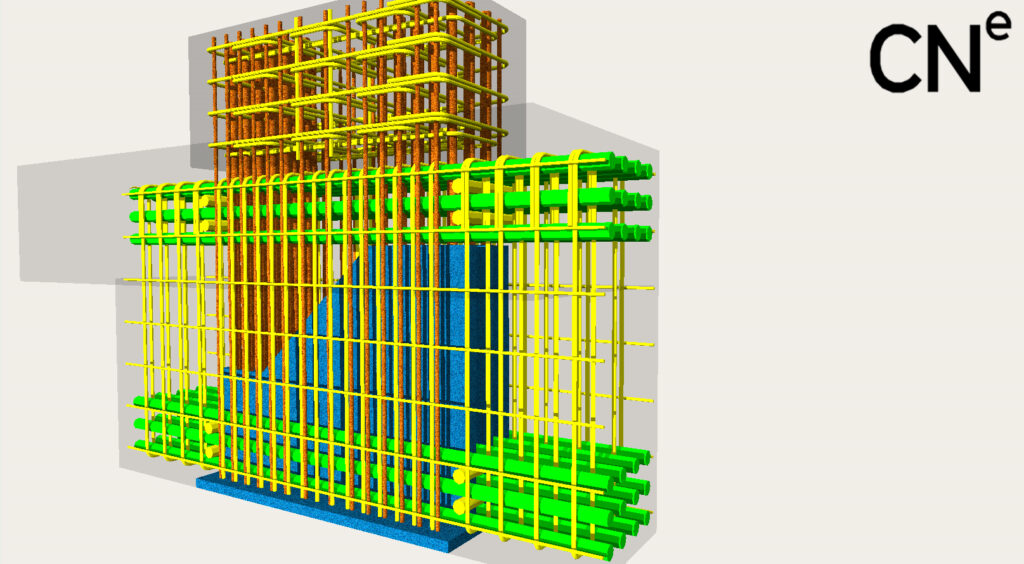

- Halfen Punching Rails were incorporated to prevent punching shear failures around column bases. These rails are essential for distributing localized forces more evenly across the slab, increasing resistance to potential shear failures and enhancing overall durability.

Automation with ALLPLAN and BIM Integration

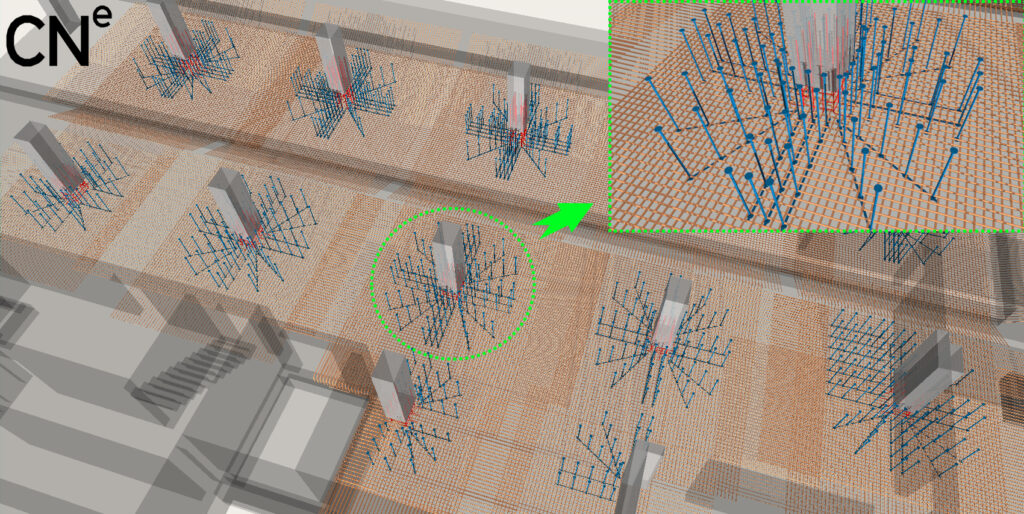

The integration of ALLPLAN software allowed us to automate the design and placement of reinforcement elements, including the Punching Rails and rebars. This automation ensured that each reinforcement component was accurately positioned according to engineering specifications, reducing manual errors and improving efficiency.

Additionally, the BIM approach enabled our reinforcement BIM teams to control and manage the placement of Punching Rails directly within the digital model. This process provided several key advantages:

- Improved Visualization: The 3D BIM model offered a detailed view of all reinforcement elements, helping to identify potential clashes or design issues early, which reduces costly adjustments during construction.

- Better Collaboration: The BIM model served as a single source of truth, improving communication among stakeholders and ensuring alignment on reinforcement requirements.

- Cost and Time Efficiency: Automated controls within ALLPLAN allowed for quick adjustments and precise placement, minimizing material waste and keeping the project on schedule.

Key Takeaways

- Targeted Reinforcement Solutions: The use of additional rebars and Halfen Punching Rails provided the necessary support to handle heavy loads and prevent structural failures in the warehouse’s bottom plate.

- Precision and Efficiency: The automation capabilities of ALLPLAN and integration with BIM allowed for accurate placement of reinforcement elements, reducing errors and facilitating a smoother construction process.

- Optimized Project Coordination: Using BIM for reinforcement planning improved coordination among project teams, optimizing resources and reducing costs.

Moving Forward

The Freilassing warehouse project highlights how combining traditional reinforcement techniques with advanced digital tools like ALLPLAN and BIM can effectively address the structural challenges of warehouse construction. This approach helps meet high standards for safety and performance while increasing project efficiency.

If your next project could benefit from a similar approach, consider how CN Europlan’s expertise in BIM-based reinforcement design can support your needs. Contact us to discuss your engineering challenges and how we can assist in delivering reliable and efficient structural solutions.