The latest project in Berlin, Germany, showcases CN Europlan’s expertise in structural engineering, with a focus on composite construction that’s built to handle the demands of a modern urban setting. This post delves into the technical details of our approach, which includes a composite column and beam system with reinforced steel profiles, engineered for durability and stability. Here’s how we’re creating a resilient and sustainable structure in the heart of Berlin.

The Core of the Structure: Composite Columns and Beams

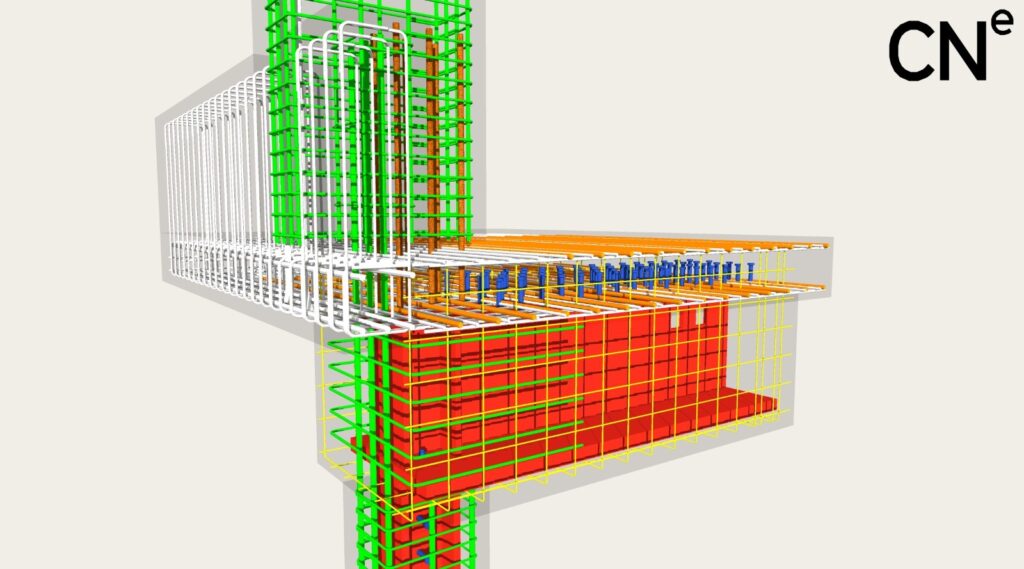

The Berlin project uses an impressive composite column and beam design, with a height and span that set a high standard in the field. Here are the essential structural specifications:

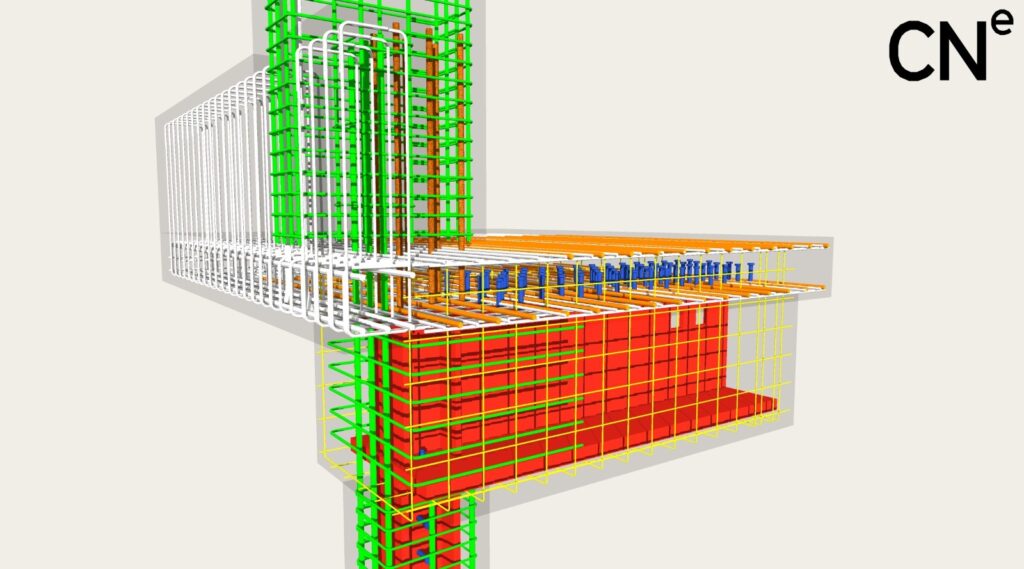

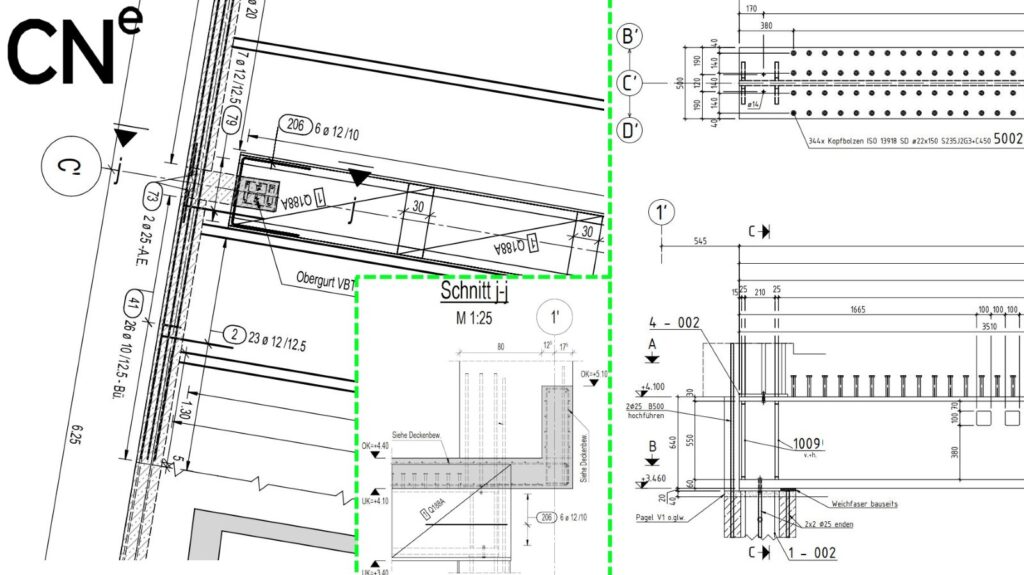

- Composite Column: With a height of 3.64 meters, this column is reinforced by a steel profile HEM240 x3580 S355J2 at its core. To add further strength, we’ve encased it with seven Ø25 mm rebars, which are reinforced with Ø10 stirrups, creating a robust central column that’s designed to support high loads effectively.

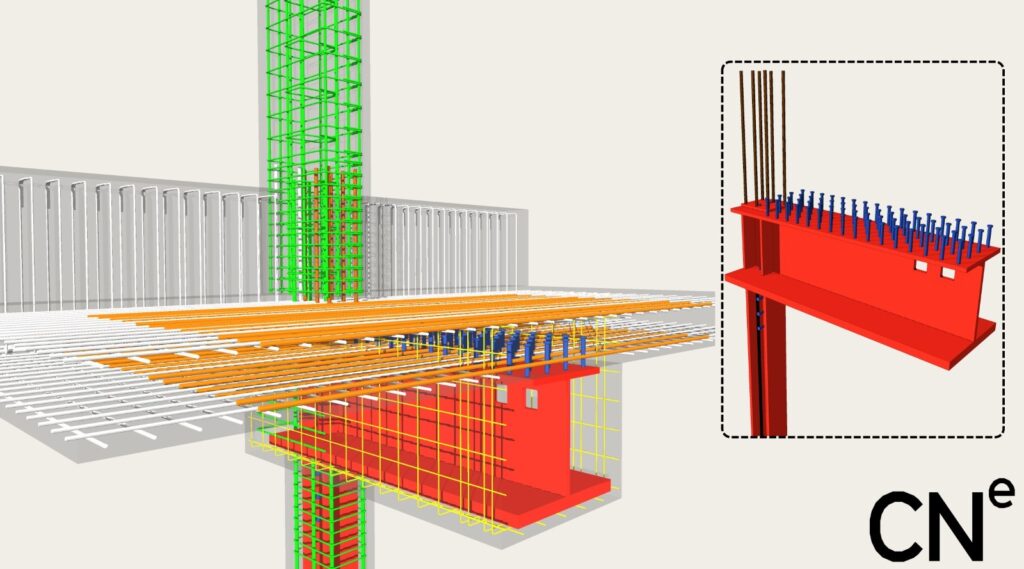

- Beam Specifications: The composite beam spans an impressive 11 meters, underscoring our commitment to long-span construction without sacrificing stability. Its main reinforcement features an I-shaped steel profile with a 60×700 mm section at the bottom and a 30×500 mm top section, interconnected by a 30×580 mm vertical profile. This unique configuration provides exceptional bending resistance and structural stability across the beam’s length.

Bolt-Head Reinforcement: Ensuring Secure Load Transfer

One of the highlights of this design is the meticulous attention to detail in the bolt-head reinforcement. More than 350 vertical bolts, each Ø22×150 mm, are anchored into the top of the steel profile, ensuring secure load transfer and a cohesive connection within the beam structure. This arrangement is crucial for distributing the load evenly and maintaining the structural integrity of the beam, especially over its extensive span.

Precision in Connection and Reinforcement

A key aspect of this project was designing an efficient connection system between the composite steel profiles and the standard reinforced concrete elements. This involved:

- Collision and Capacity Checks: We conducted rigorous checks to ensure that all reinforcing elements were placed optimally without causing structural interferences. By anticipating and solving potential clashes between composite and concrete elements, we minimized the risk of onsite adjustments, improving both the efficiency and accuracy of construction.

- Enhanced Durability: By combining steel and concrete in these critical load-bearing elements, we’ve created a structure that maximizes the benefits of both materials. The composite design ensures the beam and column can resist heavy loads and withstand environmental pressures over time.

Why This Approach Matters

Composite construction allows for greater spans and heights while ensuring resilience and efficient material use. This approach not only optimizes structural performance but also aligns with sustainability goals by reducing the need for excessive raw materials and lowering embodied carbon.

Key Takeaways

Our Berlin project exemplifies how CN Europlan pushes the boundaries of structural engineering. By integrating advanced reinforcement techniques, we’re building structures that meet the demands of modern urban environments with efficiency, precision, and durability. If you’re looking for innovative solutions in composite construction, then is CN Europlan the right contact.

Contact us to discuss how we can support your next project with structural engineering expertise tailored to your needs.