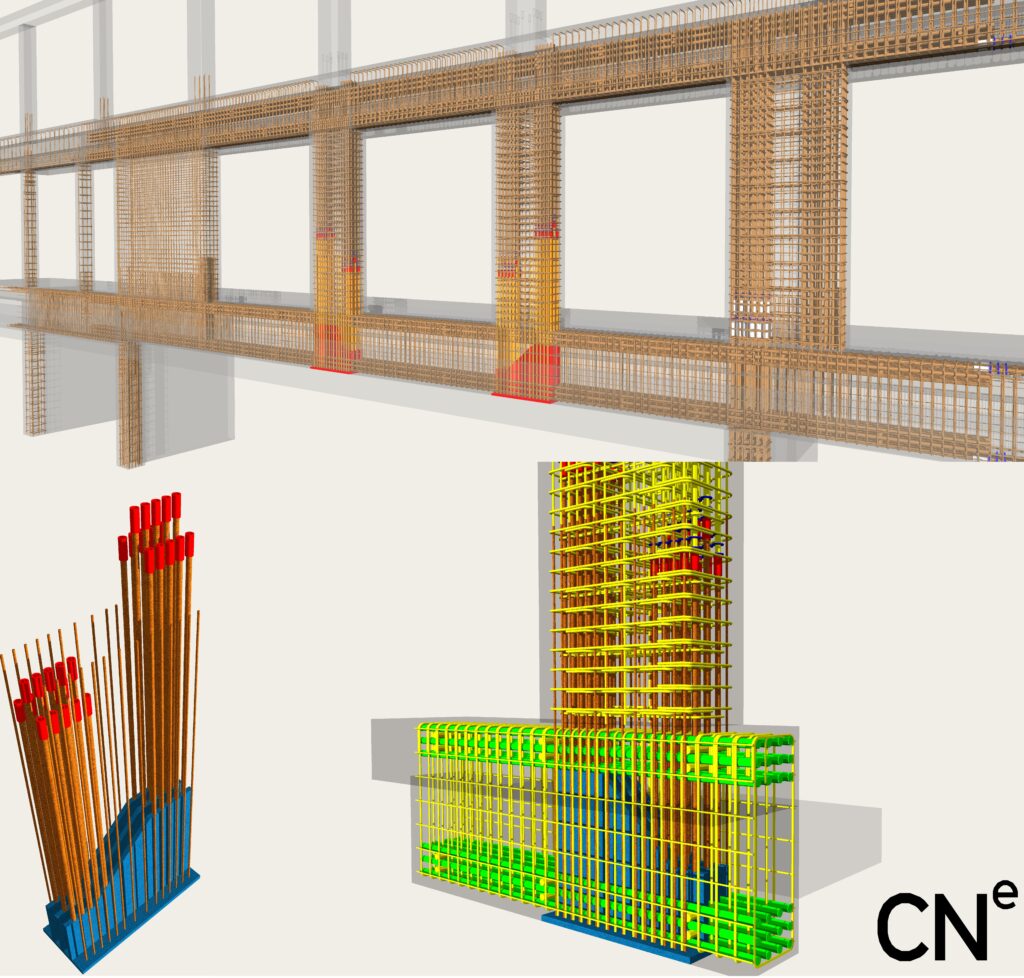

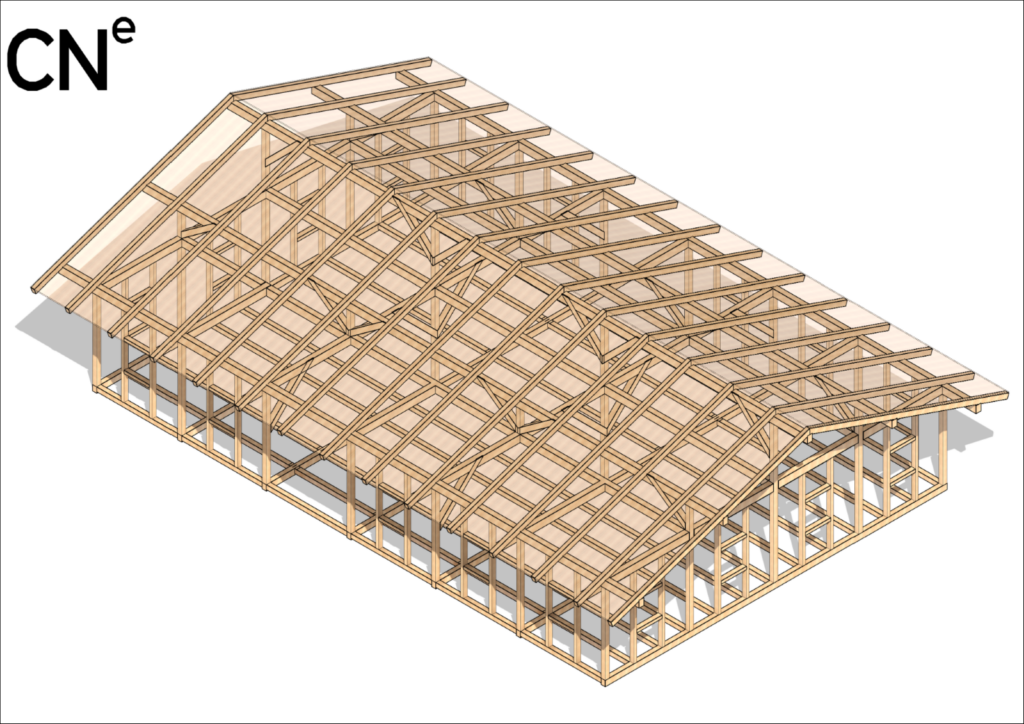

Timber structures are becoming more popular, with their natural beauty and sustainability offering a strong alternative to concrete. At CN Europlan, we use our deep experience in structural engineering to design timber buildings that are strong, efficient, and elegant. A recent example is our “Mobile Almhütte” (mobile alpine cabin) —a project that combines traditional alpine architecture with modern engineering.

The “Mobile Almhütte” is a 10x15m transportable cabin with a lightweight timber frame. It combines the charm of a classic alpine structure with modern, sustainable engineering. This project shows our approach to timber construction, using advanced design tools to ensure a strong, flexible, and portable structure.

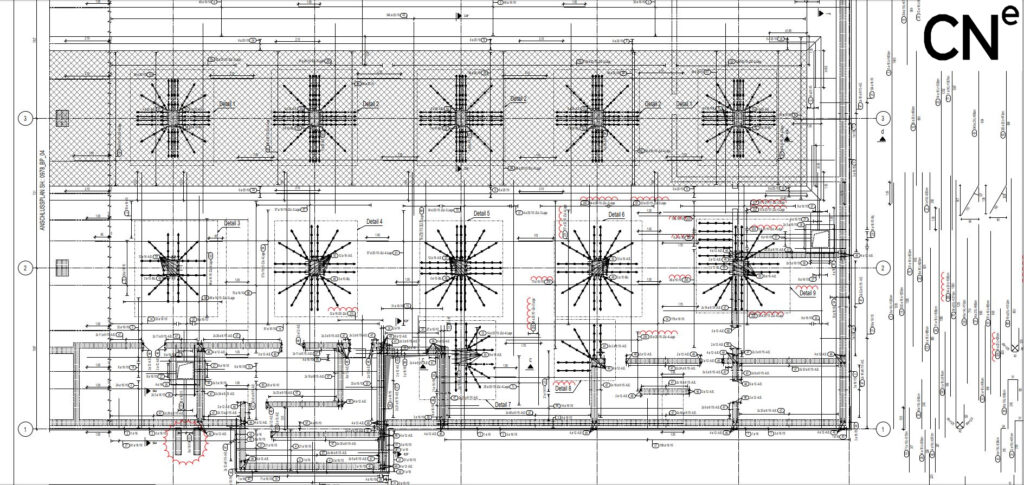

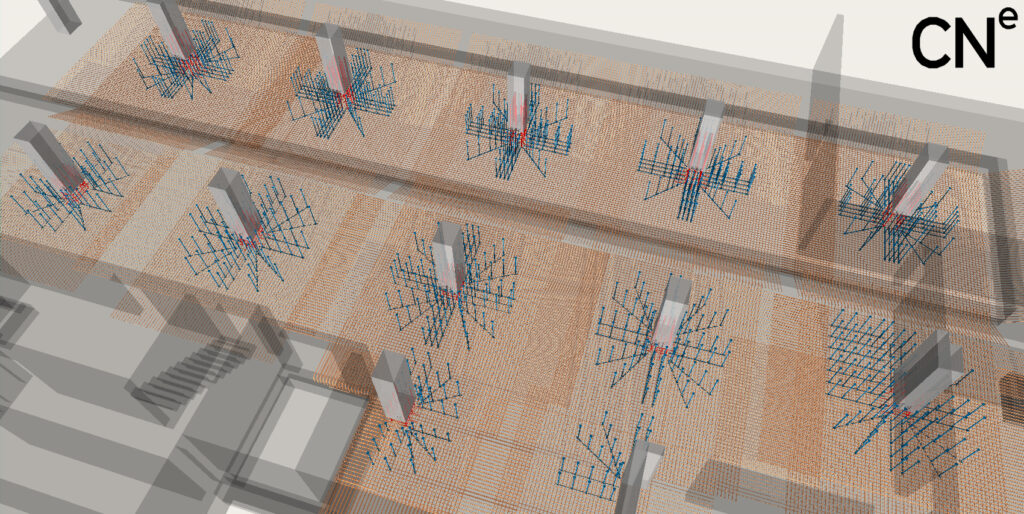

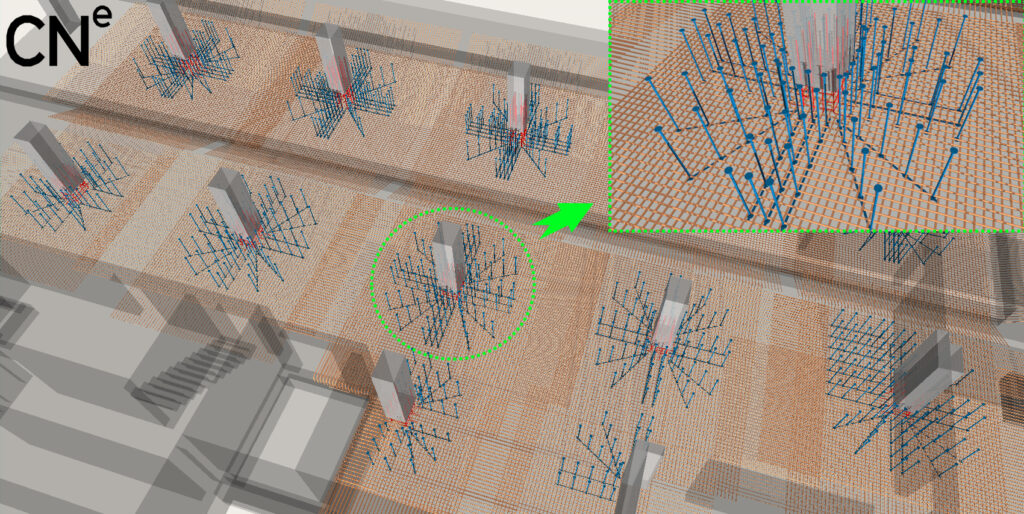

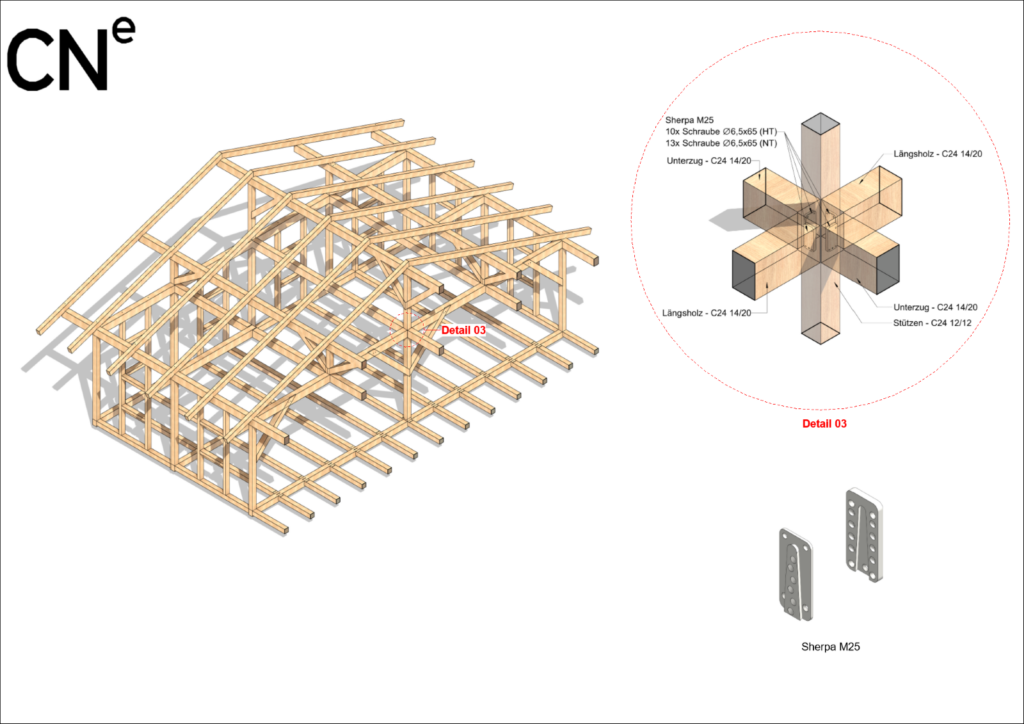

The Almhütte’s design includes a carefully engineered framework with three main girder spans (Unterzug – C24 14/20) and five secondary girder spans (Längsholz – C24 14/20), creating a reliable load-bearing system. Each joint and connection point was calculated using automated engineering software for precision and balanced weight distribution.

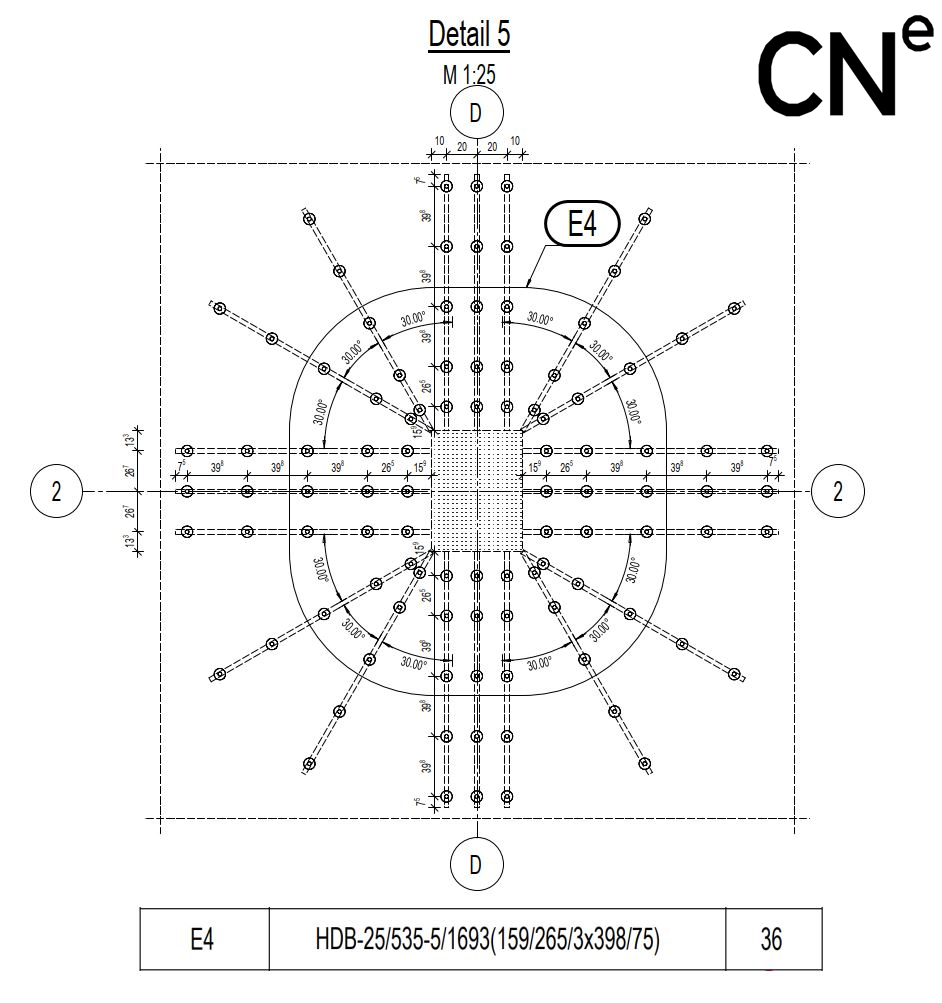

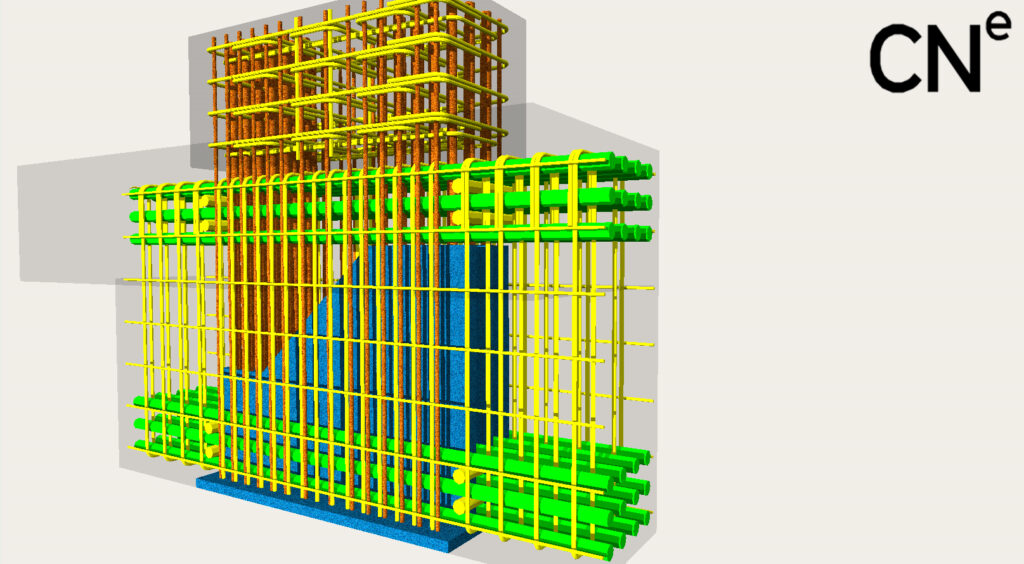

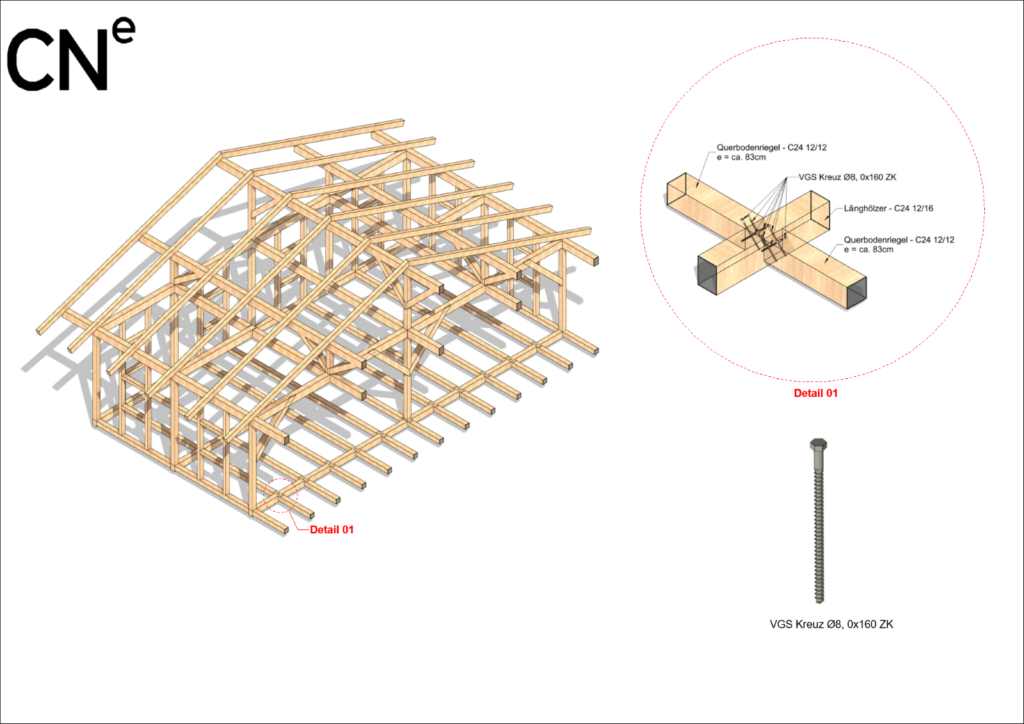

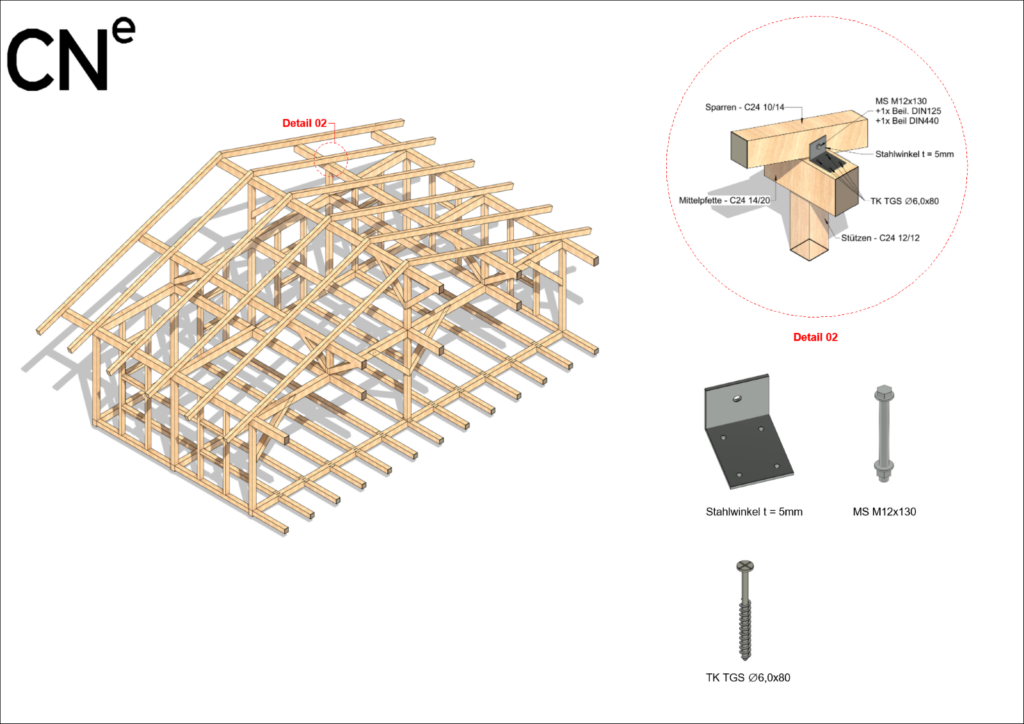

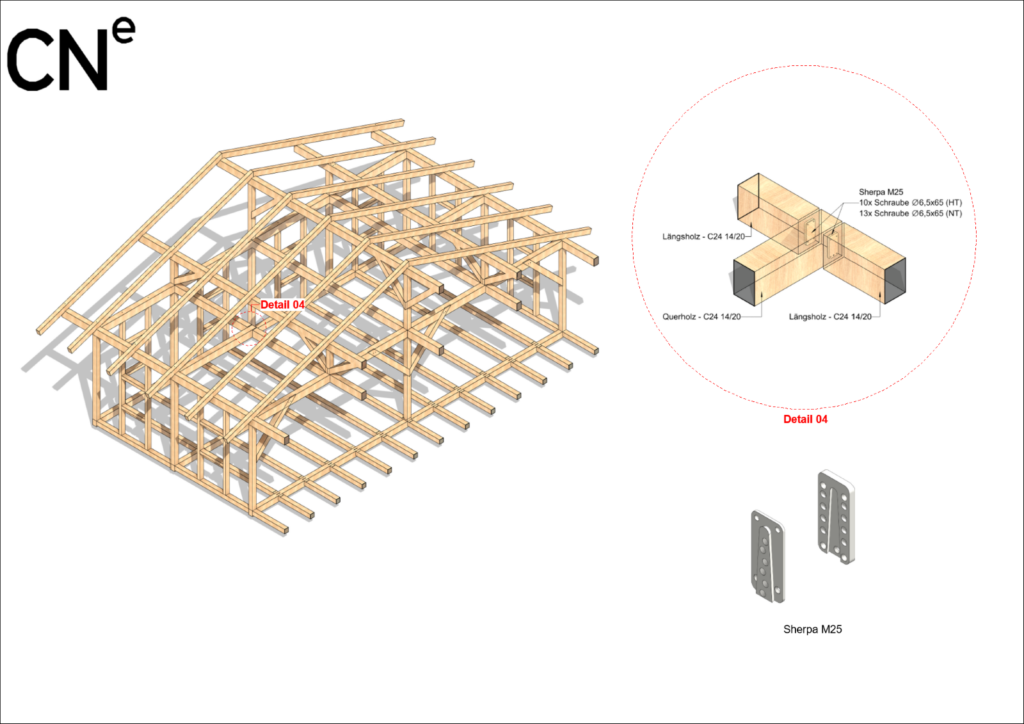

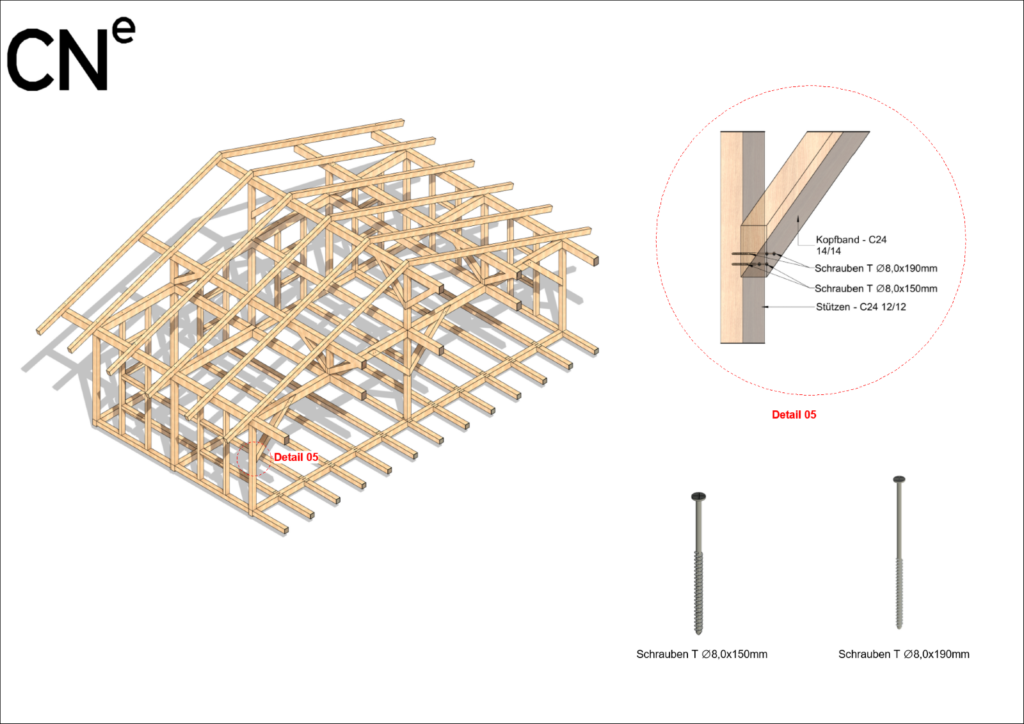

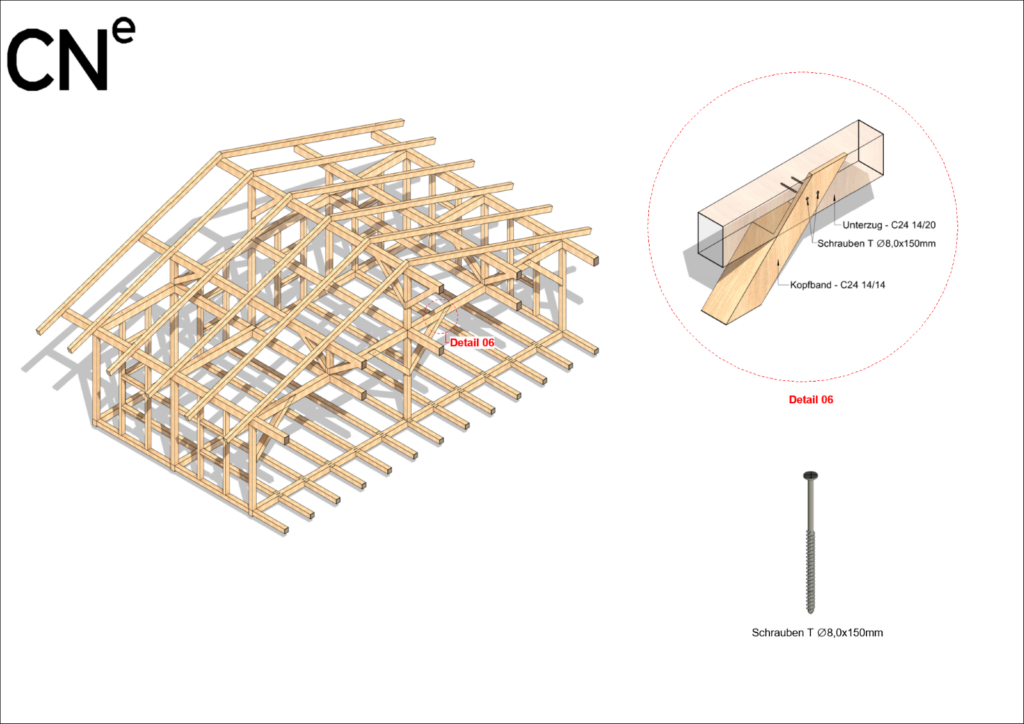

We recently added refined connection details to the Almhütte, showing how structural and aesthetic elements come together to create a strong, mobile cabin:

- Detail 01: Cross-joints between secondary girders (Querbodenregel C24 12/12 and Längsholz C24 12/16) are reinforced with VGS Kreuz screws (Ø8, 0x160 ZK). This provides a stable connection while allowing flexibility during transport.

- Detail 02: Steel angle brackets (5mm thick) join the main girders with vertical posts (Mittelpfette C24 14/20 and Stützen C24 12/12), secured with MS bolts (M12x130) and high-torque screws (TK TGS Ø6.0×80) for strong, load-resistant connections.

- Detail 03: Sherpa M25 connectors enhance the main load-bearing intersections between longitudinal and cross beams. These connectors, designed for timber, allow efficient force distribution across the cabin’s structure.

- Detail 04: A cross-connection in the primary framework, secured with Sherpa M25 connectors and screws (Ø6.5×65 HT/NT), strengthens the load-bearing system for added durability.

- Detail 05: Diagonal bracing (Kopfband C24 14/14) is attached to supporting columns (Stützen C24 12/12) with large screws (Ø8.0x190mm and Ø8.0x150mm), adding resistance against lateral movement and improving stability.

- Detail 06: Another diagonal connection, fastening the beam (Unterzug C24 14/20) to the bracing (Kopfband C24 14/14), uses additional screws (Ø8.0x150mm) for structural support, further strengthening the Almhütte.

Each of these connections is designed for strength and ease of assembly, which is important for a mobile structure. The automated design ensures all components fit smoothly, which improves both the cabin’s stability and portability.

The Mobile Almhütte project shows CN Europlan’s commitment to quality and innovation in timber construction. From automated design to careful material selection, every detail is aimed at creating sustainable, strong structures. Whether you need a permanent building or a mobile solution, CN Europlan can make your vision a reality with expert engineering and sustainable materials.

Key Takeaways

- Timber Expertise: CN Europlan’s experience with both timber and concrete allows us to handle a range of structural needs.

- Precision Design: Advanced software helps us create accurate, load-optimized connection details.

- Built for Mobility: The Mobile Almhütte is a versatile timber structure, designed for both stability and easy transport.

- Strong Connections: Well-designed joints provide stability and efficiency for the cabin.

If you’re interested in exploring the possibilities of timber construction, CN Europlan is ready to bring experience and knowledge to your project. Contact us to discuss how our designs and engineering skills can help bring your ideas to life.